Urea

Base chemical for important finals

Urea

Base chemical for important finals

Urea Melting

Urea is used in several applications like

- Nitrogen fertiliser

- Base chemical in resin, paint and glue production

- Up-stream product of hydrazine, melamine and amidosulfonic acid

- Cosmetics

- Animal feed and

- Ice melting

Some applications of urea need the addition of other ingredients in order to provide a more useful product. Therefore the urea granules from the urea production process need to be melted and mixed with other materials.

E. g. nitrogen fertilizeer: Temperatures of about 130°C support Biuret creation by the combination of two urea molecules and the formation of one ammonia molecule. The Biuret concentration of the final product should be low because Biuret impairs plant growth. Therefore the residence time under elevated temperature must be as short as possible.

Melting and mixing tasks are very effectively realised in a horizontal thin film dryer.

Urea melting and mixing to final product mixture

Characteristics of urea melting

Contrary to a drying process the feed is dry and solid and the product is liquid. There is nearly no evaporation of the feed material and hence no vapour condensation.

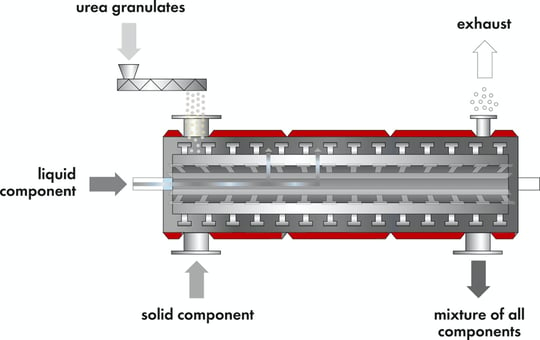

The urea granules are fed into the dryer and melted by indirect heating. Due to the short residence time Biuret generation is minimal. Additional solid components can be added through a separate nozzle. Liquid components can be injected through the rotor of the dryer. The feed components are mixed during their way through the dryer to the final product.

Looking at urea melting near the inlet of the dryer shows that horizontal thin film dryers are even able to realise high heat transfer rates to solid products. This opens another range of applications, such as melting of solids and cooling of solid products from drying processes.