Sewage Sludge

Drying

Our solution to make sludge a useful product

Sewage Sludge

Drying

Our solution to make sludge a useful product

Sewage Sludge Drying

The products leaving a waste water treatment plant are cleaned waste water and solids, known as sewage sludge or biosolids. While the clean water can be discharged into a river or even be reused after further treatment, the final disposal or use of the solids needs some additional efforts. Depending on the sludge quality and the local situation the sludge can be finally disposed to landfill, used as a fertilizer and soil conditioner or used as an energy source. In the near future phosphates will be recovered from the sludge.

The usage of the sludge as a well-defined product becomes more and more prominent. Prior to full drying treatment steps for transforming the sludge to a valuable product are neeeded. SMS offers sludge drying systems for treatment of sludge from municipal as well as from industrial waste water treatment plants. Variations of this sludge treatment process are:

Pre-drying up to

- 35 to 50 % dry solid content before incineration in fluidised bed incinerators

- 65 to 75 % dry solid content before combined incineration with garbage, composting or landfill

Full drying up to 85 to 95 %

- before thermal utilisation as bio-fuel for cement kilns, coal fired power stations, pyrolysis, gasification or other conversion processes

- before composting and agricultural usage as fertilizer and for soil reclamation

In all these drying processes the thin film dryer is the first choice.

SMS sludge drying process

The core of the installation is the horizontal thin film dryer. Depending on the application the evaporation capacity per dryer is up to 8 tons of water per hour.

The unique benefits of the SMS sludge drying system are:

- one-stage operation passing the sticky or pasty phase

- no backmixing of dried product

- minimum amount of waste gas

- self-inerting by evaporated water

All these advantages make the thin film sludge dryers very successful. More than 100 machines are installed worldwide.

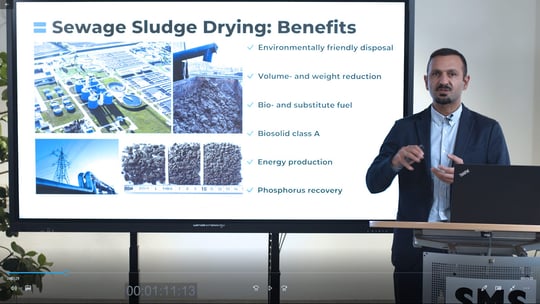

A product with value

Explore the advanced technology that transforms sewage sludge into a valuable and sustainable product. This process is detailed in an engaging and informative 10-minute video, which delves into the innovative methods and cutting-edge techniques used to convert waste into something beneficial. Learn about the environmental impact, the science behind the transformation, and the potential applications of the end product, all presented in a clear and concise manner.

Contact our specialist in excellent solutions

Önder Demiralay

Sludge drying

Tel. +49 2421 705 42

Worldwide

"Our thin-film dryers are designed to offer exceptional efficiency and dependability in the drying of sewage sludge, presenting an eco-friendly solution that reduces energy use while enhancing the quality of the output."

Get your free copy!

Explore the detailed contents of our sewage sludge drying flyer to discover comprehensive information, including the latest technologies, benefits, and practical applications of our innovative solutions.