-1.jpeg?width=576&height=192&name=Fertigung%20(3)-1.jpeg)

Biodiesel /

Glycerine

Highly valuable products from natural resources

Biodiesel /

Glycerine

Highly valuable products from natural resources

Biodiesel and Glycerine Plants

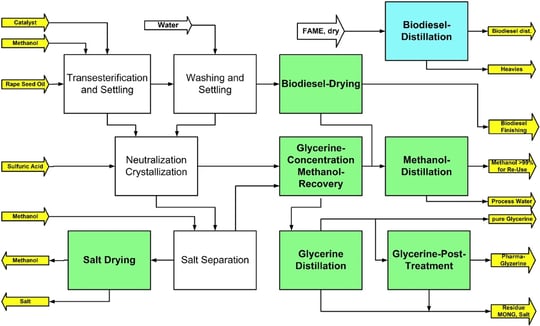

Buss-SMS-Canzler is specialised in the delivery of the following plant components:

Biodiesel Drying

Our types of flash or falling film evaporators reach specification-conform biodiesel with residual moistures below 200 ppm water.

Biodiesel Distillation

The biodiesel from used edible oils must be improved by distillation. For the production of specification-conform qualities Buss-SMS-Canzler supplies entire distillation plants for single- and multi-stage cleaning.

Valuable By-products

For the processing of by-products from the biodiesel production Buss-SMS-Canzler delivers established technology for important process stages, such as the drying of potassium sulphate.

Methanol Distillation

Our distillation column recovers the excess methanol from the aquaous, glycerine containing mixture produced during transesterification. The recovered methanol is pure enough to be reused in the transesterification process.

Glycerine Concentration

The forced circulation evaporation plant dehydrates the glycerine to a large extent and removes the methanol. Vapour cleaning almost completely prevents glycerine losses.

Glycerine Distillation

The glycerine column processes the dehydrated glycerine to a high-purity product. The salty concentrate extracted from the column is processed in a special thin film evaporator. The glycerine vapours are re-circulated to the distillation column and the residue is discharged either as liquid or as powder. This ensures a high yield of glycerine.

Glycerine Bleaching

Downstream cleaning stages deodorise and bleach the technically pure glycerine and improve the colour index, resulting in pharmaceutical quality glycerine.

We have delivered process stages and components for biodiesel plants with capacities up to 250,000 to/a of biodiesel and 30,000 to/a of glycerine.

Glycerine Recovery from MONG and salt

The raw glycerine containing, e.g. MONG and a salt (e.g. NaCl), is fed to a vertical thin film dryer by an eccentric screw pump. Typically, the operating pressure is within a range of approx. 2-5 mbar and the operating temperature, depending on the individual conditions at site, is between 190 - 250°C.

The glycerine is evaporated in the thin film dryer which is equipped with a suitable separator to prevent solid carry-over. Thereafter the vapours are condensed, so that the residual stream is a mixture consisting of salt and MONG which is discharged to atmosphere by a suitable vacuum lock.