Intermediate

Pharmaceutical Products

Drying determines final product quality

Intermediate

Pharmaceutical Products

Drying determines final product quality

Intermediate pharmaceutical products

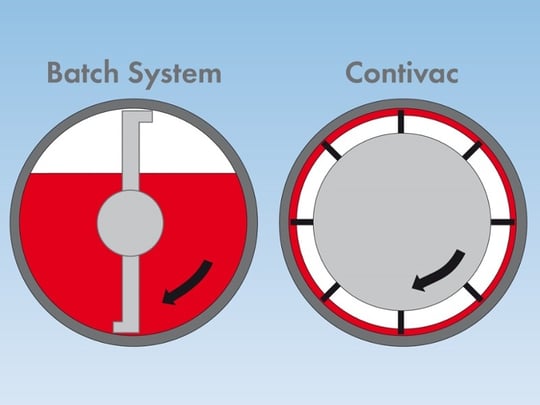

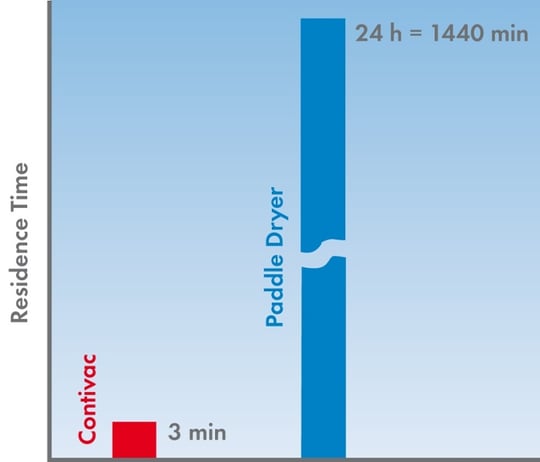

Drying of intermediate pharmaceutical products is an extremely quality-determining process step. The thin film dryer Contivac is the most adequate dryer to handle such demanding targets. This dryer operates with the same thin film principle as described for the horizontal thin film dryer. Compared to the paddle dryer, the product hold-up in the Contivac is small and the residence time is extremely short. Reducing the residence time by 500 times has the following effects:

- Reduction of side reactions

- Reduction of colour changes

Fast drying is only one of the great advantages of the Contivac. It opens many others possibilities for pharmaceutical products. Additional substances can be evenly sprayed on the thin film in the Contivac with rotating nozzles. In addition, the heating jacket can be split into different heating zones and further feed nozzles can be fitted at several positions. This allows a most flexible design in order to produce thermally sensitive pharmaceutical products.

Comparison of product quantity in a conventional paddle and a Contivac NDP thin film dryer

Comparison of the residence time

View into the Contivac dryer - rotor with rotor elements and support for dismantling