Thin Film Processors

Viscon & Filmtruder

Intensive surface renewal as function principle

Thin Film Processors

Viscon & Filmtruder

Intensive surface renewal as function principle

Complete systems for processing of highly viscous products

Filmtruder and Viscon processors are specialised in the concentration, purification and devolatilisation of products with viscosities up to 10,000 Pas and are characterised by the following properties:

- Short residence time

- High and homogeneous product quality

- Unique surface renewal and film distribution for high level of devolatilisation

- Large free vapour space in relation to low product hold-up

- Wide range of product grades handled in one unit

Examples for application fields are

- Resins

- Adhesives

- Cellulose fibres

- Thermoplastics

- Recycling materials

- Biopolymers

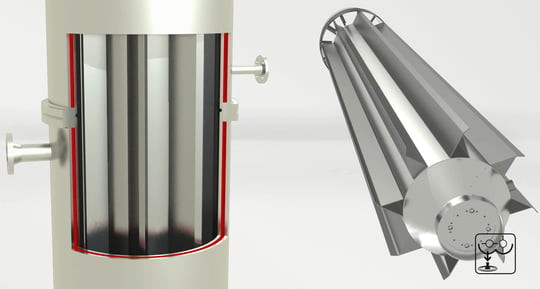

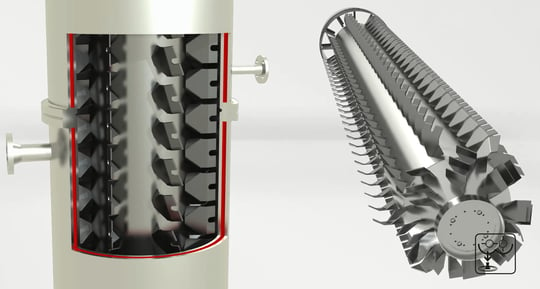

The rotor of the vertical thin film processors Filmtruder and Viscon mechanically generates a thin product film on the inner wall of the heated body. The intensive surface renewal creates excellent conditions for heat and mass transfer and produces a high level of devolatilisation.

The design and arrangement of the rotor blades enable the transport and discharge of viscous products. The large free vapour space compared to the low product hold-up allows a high evaporation ratio in a single pass without the risk of any product being carried into the condensation system.

VISCON rotor

FILMTRUDER rotor