Chemicals

The base for plenty of products for a better life

Chemicals

The base for plenty of products for a better life

Applications – process-specific equipment

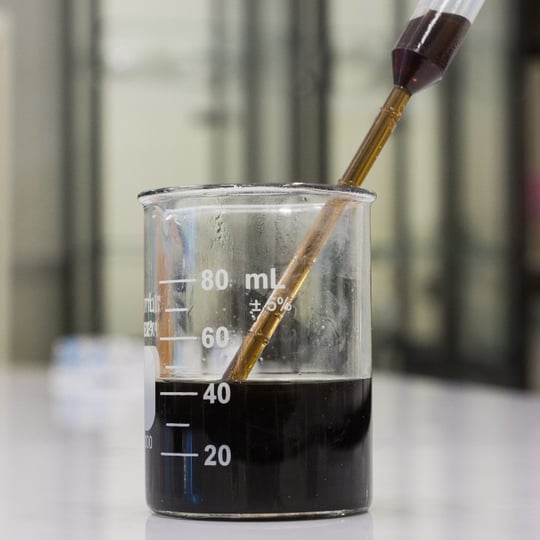

The chemical industry requires specialised process equipment which is adapted to the specific needs of each production process. Among others, the tasks to be covered by the equipment consist of the purification of the desired product from remaining monomers, the separation of catalysts from reaction products, the recycling of product from waste streams and the product split into target fractions.

The SMS equipment covers a wide range of process tasks in the chemical industry, based on a long-term experience and a very special process knowledge.

Monomers:

- Acrylonitrile

- Acrylic ester

- Bisphenol A

- Butanediol (BDO)

- Butene-1

- Caprolactam

- Epichlorohydrin

- Glycol

- Hexamethylen diisocyanate (HDI)

- Lauryl lactam

- Maleic anhydride

- Methyl acrylate

- Methyl diphenyl diisocyanate (MDI)

- Phtalic anhydride

- Styrene

- Toluene diisocyanate (TDI)

- TDI recovery

- Vinyl acetate

Surfactants:

- Ethoxylate

- Sulfonate

- Synth. washing agents

- Tenside

- Alkyl polyglycosides (APG)

Amines:

- Ethylene diamine

- Hexamethylene tetramine

- Hydrazine

- Morpholine

- Triethanolamine

Fertilizers:

- Ammonium nitrate

- Urea

Insecticides:

- Benzene hexachloride

- Diazinone

- Pyrethrum extract

Plasticizers:

- Dioctyl phtalate

- Nonylic phenole

- Phtalate

- Tricresyl phosphate

Esters:

- Amino ester

- Butyl stearate

- Dicarboxylic ester

- Ethyl acetate

- Glycol ether

- Malonic ester

- Monostearate

Latex:

- Acrylonnitrile-styrene latex

- Butadien-styrene latex

- Rubber latex

- PVC latex

Acids:

- Acetic acid recovery

- Terephthalic acid

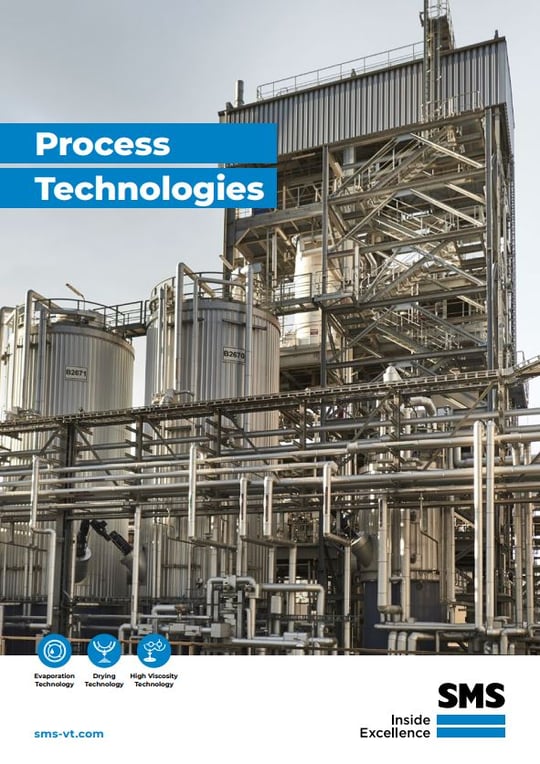

Get your free copy!

Inside Excellence in process technologies: We are number 1 in thin film evaporation technology and a global leader in drying and high viscosity technology. Take a look inside our technology brochure:

Technologies

Evaporation Technology

We offer the world’s largest selection of thin film evaporators and build customer-specific equipment for the evaporation of materials which are difficult to process such as viscous, fouling, and heat sensitive liquids.

Drying Technology

Depending on the requirements, we combine and customise drying processes and components to suit the product properties so that, for example, toxic or explosive materials can be safely and efficiently processed.

High Viscosity Technology

Our thin film processors and large volume reactors for the manufacture and preparation of polymers are world leaders and guarantee the very highest quality and efficiency as well as excellent process results.

References

-1.jpg?width=576&height=371&name=Buss%20SMS%20NLN%201400%20Titan%20(3)-1.jpg)

Quality powered by experience

Our customers expect us to be uncompromising and unparalleled in our search for quality.

- Experience - the foundation of SMS quality

SMS today combines the knowledge and skills of Samesreuther-Müller-Schuss, Luwa, Canzler and Buss, resulting in outstanding quality and the unusally long-working life of our equipment. - Our way to quality - quality management

SMS products meet all applicable and relevant quality standards, codes, regulations, and directives. - Workmanship - 100 % Made in Germany

SMS products are manufactured using the most demanding levels of workmanship to ensure that they reliable and safely perform their task.